Explain Different Types of Control Charts

Attribute data are data that are counted for example as good or defective as possessing or not possessing a particular characteristic. The centerline in the chart is the average of all the ranges.

Control Chart Rules And Interpretation Bpi Consulting

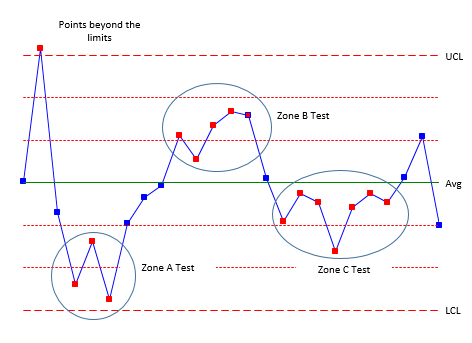

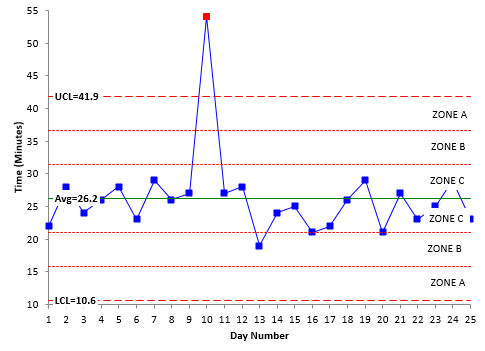

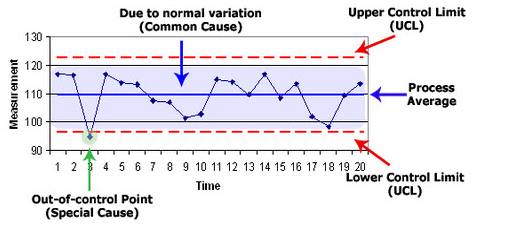

Two other horizontal lines called the upper control limit UCL and the lower control limit LCL are also shown on the chart.

. The moving range difference between sequential measurements is used to calculate control limits for the chart. 1 the ideal 2 the threshold 3 the brink of chaos and 4 the state of chaos Figure 1. Control charts are a key part of the management reporting process that have long been used in manufacturing stock trading algorithms and process improvement methodologies like Six Sigma and Total Quality Management TQM.

Individuals XMR chart comprised of X chart top and R chart bottom from Introduction to Control Charts Run Charts. When you start a new control chart the process may be out of control. Its similar to a c chart as it shows you various groups of items over time except that the r.

X-bar R charts EWMA charts P charts for data that is not time-ordered. For defective and subgroup or sample size is same or may vary. The Four Process States Processes fall into one of four states.

Variable Data Charts IX-MR individual X and moving range Xbar-R averages and ranges Xbar-s averages and. There are various types of control charts that are used for different purposes. Xbar-R Control Chart.

P Np C and U Charts. The chart is particularly advantageous when your sample size is relatively small and constant. Individuals charts are also called XMR or XmR charts to denote the individual X values and the moving ranges.

Types of Control Charts Control Charts are basically of 7 types as it all depends upon the data type. I-MR Chart X Bar R Chart and X Bar S Chart. There are various types of control charts which are broadly similar and have been developed to suit particular characteristics of the quality attribute being analyzed.

Lets make it with Excel and Spanish TemplateExcel Template Whats SPC Statistical Process Control and MSA Measurement System Analysis. Variable control charts for measured data. SPC control chart software for production offline analysis or link to ERPLIMS.

If we have a continuous data type then we can use 3 types of Control Charts ie. When they were first introduced there were seven basic types of control charts divided into two categories. The standard deviation value s for these charts is determined by the same method as the standard deviation for the distribution platform.

Numerical data When your data is in the form of a continuous type of data we will use control charts like X bar chart R bar chart S bar chart. Now in this attribute data type there are 4 types control chart. Use for defect and subgroup or sample size is same or may vary.

The control limits are placed such that the distance between them and the centerline is 3s. Control charts are simple robust tools for understanding process variability. Use for defect and Sample size is fixed.

If so the control limits calculated from the first 20 points are conditional limits. Ad Dashboards Alert emails process monitoring control charts enhanced reports. Control charts ushered in by Walter Shewhart in 1928 continue to provide real-time benefits in todays modern factories.

Ad Over 27000 video lessons and other resources youre guaranteed to find what you need. Data Analysis SPC Statistic Process Control. The types of Control Charts are Variable Control Charts and Attribute Control Charts.

Variable Control Charts Range R Control Chart This type of chart shows the variability within the process. C Chart C chart is a type of control chart that displays the number of non conformities that appear in a given category objects that are out of spec. Two broad categories of chart exist which are based on if the data being monitored is variable or attribute in nature.

The purpose of a control chart is to set upper and lower bounds of acceptable performance given normal variation. Attribute control charts for counted data. Several other types of control charts are available for advanced Six Sigma practitioners typically Black Belts and Master Black Belts.

Lets just take a look at them. Individual-X Moving Range Chart. Xbar and Range Chart The most common type of SPC chart for operators searching for statistical process control the Xbar and Range chart is used to monitor a variables data when samples are collected at regular intervals.

Variable and Attribute Control Charts. Individual and Moving Range I-MR X Bar Range Chart X Bar R X Bar Sample Chart X-BarS 3 Chart I-MR-R Master Black Belt. Control charts fall into two categories.

It is of three types. For every set it records the smallest and largest readings. As each new data point is plotted check for new out-of-control signals.

It is best for small sample sizes for instance a small size 10. For defective and Sample size is fixed. Variable Control Charts plot statistics from the measurement data such as height length width etc.

There are two main categories of control charts. Data is obtained in different types all of the same size. The two broad categories of control charts are.

X bar control chart. Levey Jennings Charts This chart displays a mean process based on a long-term sigma with control limits. These control limits are chosen so that almost all of the data points will fall within these limits as long as the process remains in.

An r chart is a control chart that shows you the range of a group of items of no more than 10 items. Attribute data When your data is in the form of an attribute or count form of data we will use control charts like P chart U chart C chart Attribute data are the number of defects defective units etc. If we have a discrete data type then we use the 4 types of Control Charts.

Out-of-Control Signals Continue to plot data as they are generated. Figure 1 Control Chart. Variable data are data that can be measured on a continuous scale such as a thermometer a weighing scale or a tape rule.

Within these two categories there are seven standard types of control charts.

Control Chart Rules And Interpretation Bpi Consulting

Comments

Post a Comment